Product (228)

-

Filter Regulator Lubricator

(8)

- Air Source treatment (27)

- Air cylinders (29)

- Air operated valves (44)

- Air Solenoid valves (22)

- Brass Push in fittings (11)

- Air tube fittings (70)

- Brass ball valves (5)

- Air blow guns (5)

- Vacuum Ejector (6)

- Hydraulic cylinders (1)

Valves' knowledge (1)

News (30)

Credit Report

Products Index

Company Info

E.DO TOOLS CO.,LIMITED [China (Mainland)]

Business Type:Manufacturer

City: Ningbo

Province/State: Zhejiang

Country/Region: China (Mainland)

News

About Pneumatic Cylinders

Pneumatic cylinders (sometimes known as air cylinders) are mechanical devices which produce force, often in combination with movement, and are powered by compressed gas (typically air).

To perform their function, pneumatic cylinders impart a force by converting the potential energy of compressed gas into kinetic energy. This is achieved by the compressed gas being able to expand, without external energy input, which itself occurs due to the pressure gradient established by the compressed gas being at a greater pressure than the atmospheric pressure. This air expansion forces a piston to move in the desired direction. The piston is a disc or cylinder, and the piston rod transfers the force it develops to the object to be moved.

Operation General

General

General

Once actuated, compressed air enters into the tube at one end of the piston and, hence, imparts force on the piston. Consequently, the piston becomes displaced (moved) by the compressed air expanding in an attempt to reach atmospheric pressure.

Fail safe mechanisms

Pneumatic systems are often found in settings where even rare and brief system failure is unacceptable. In such situations locks can sometimes serve as a safety mechanism in case of loss of air supply (or its pressure falling) and, thus, remedy or abate any damage arising in such a situation. Due to the leakage of air from input or output reduces the pressure and so the desired output.

Types

Although pneumatic cylinders will vary in appearance, size and function, they generally fall into one of the specific categories shown below. However there are also numerous other types of pneumatic cylinder available, many of which are designed to fulfill specific and specialised functions.

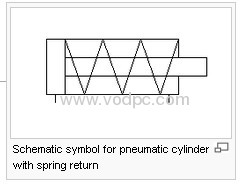

Single acting cylinders

Single acting cylinders (SAC) use the pressure imparted by compressed air to create a driving force in one direction (usually out), and a spring to return to the "home" position.

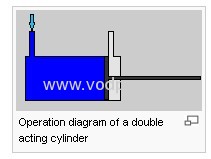

Double acting cylinders

Double Acting Cylinders (DAC) use the force of air to move in both extend and retract strokes. They have two ports to allow air in, one for outstroke and one for instroke.

Other types

Although SACs and DACs are the most common types of pneumatic cylinder, the following types are not particularly rare:

Rotary air cylinders: actuators that use air to impart a rotary motion

Rodless air cylinders: These have no piston rod. They are actuators that use a mechanical or magnetic coupling to impart force, typically to a table or other body that moves along the length of the cylinder body, but does not extend beyond it.

Some rodless cylinder details

Some rodless types have a slot in the wall of the cylinder. That slot is closed off for much of its length by two flexible metal sealing bands. The inner one prevents air from escaping, while the outer one protects the slot and inner band. The piston is actually a pair of them, part of a comparatively long assembly. They seal to the bore and inner band at both ends of the assembly. Between the individual pistons, however, are camming surfaces that "peel off" the bands as the whole sliding assembly moves toward the sealed volume, and "replace" them as the assembly moves away from the other end. Between the camming surfaces is part of the moving assembly that protrudes through the slot to move the load. Of course, this means that the region where the sealing bands are not in contact is at atmospheric pressure.

Another type has cables (or a single cable) extending from both (or one) end[s] of the cylinder. The cables are jacketed in plastic (nylon, in those referred to), which provides a smooth surface that permits sealing the cables where they pass through the ends of the cylinder. Of course, a single cable has to be kept in tension.

Still others have magnets inside the cylinder, part of the piston assembly, that pull along magnets outside the cylinder wall. The latter are carried by the actuator that moves the load. The cylinder wall is thin, to ensure that the inner and outer magnets are near each other. Multiple modern high-flux magnet groups transmit force without disengaging or excessive resilience

Sizes

Air cylinders are available in a variety of sizes and can typically range from a small 2.5 mm air cylinder, which might be used for picking up a small transistor or other electronic component, to 400 mm diameter air cylinders which would impart enough force to lift a car. Some pneumatic cylinders reach 1000 mm in diameter, and are used in place of hydraulic cylinders for special circumstances where leaking hydraulic oil could impose an extreme hazard.

Pressure, radius, area and force relationships

Although the diameter of the piston and the force exerted by a cylinder are related, they are not directly proportional to one another. Additionally, the typical mathematical relationship between the two assumes that the air supply does not become saturated. Due to the effective cross sectional area reduced by the area of the piston rod, the instroke force is less than the outstroke force when both are powered pneumatically and by same supply of compressed gas.

The relationship, between force on outstroke, pressure and radius, is as follows:

Cord

This is derived from the relationship, between force, pressure and effective cross-sectional area, which is:

F = p A\,

With the same symbolic notation of variables as above, but also A represents the effective cross sectional area.

On instroke, the same relationship between force exerted, pressure and effective cross sectional area applies as discussed above for outstroke. However, since the cross sectional area is less than the piston area the relationship between force, pressure and radius is different. The calculation isn't more complicated though, since the effective cross sectional area is merely that of the piston less that of the piston rod.

For instroke, therefore, the relationship between force exerted, pressure, radius of the piston, and radius of the piston rod, is as follows:

Where:

- F represents the force exerted

- r1 represents the radius of the piston

- r2 represents the radius of the piston rod

- π is pi, approximately equal to 3.14159.

The pneumatic cylinders designed for educational use typically have transparent outer sleeves (often plexiglass), so students can see the piston moving inside.

The pnuematic cylinders designed for cleanroom applications often use lubricant-free Pyrex glass pistons sliding inside graphite sleeves.

Pre Page:

About Filter, Regulator, Lubricator